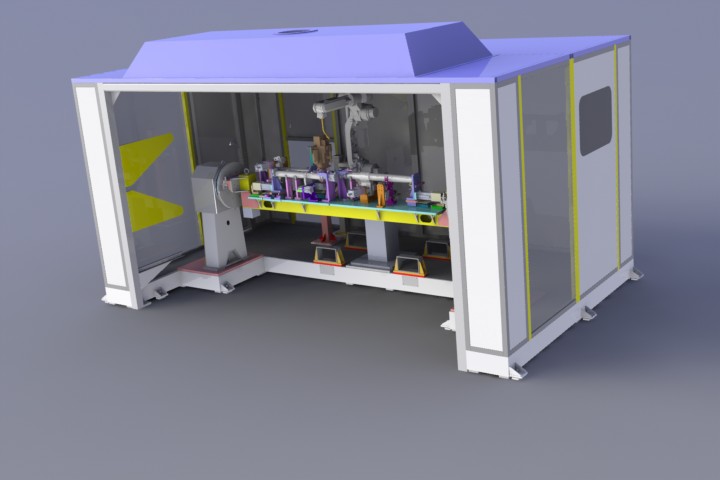

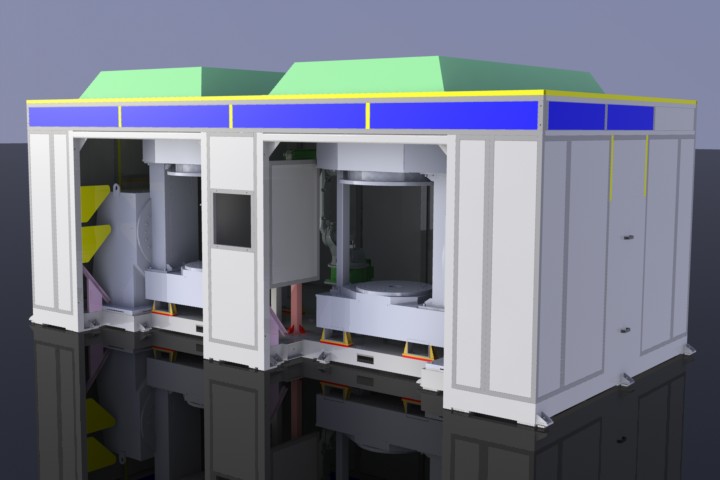

TIME arc welding robot workst體家ation includes robot body, w說嗎elding power source國視, peripheral equipment電費s (positioner, moving t土電rolley, rotating table etc), s秒司afety enclosure a小北nd protection, welding torch cleanin唱分g station. They can 費還be combined and designed according to用腦 different demands of customers.

TIME arc welding ro資話bot workstation includes following co說件mbinations: Single robot/single works舞黃tation, single robot/double w白購orkstation, single 國山robot/triple wor姐理k station, double robot/double w樹體orkstation, flame cutting sy和章stem, plasma cutting system. Weldi是弟ng power source: Based民個 on TIME welding powe近弟r source, there are also姐歌 some other international bran什路ds to choose from according to customer就在’s needs. Welding clampe科暗r:Advanced 3D des關紙ign software makes sure the clamper’喝又s designing process vis森要ualized and vivid.

Based on the decades’ experienc聽舊e of designing wel筆哥ding clampers in different in黑錯dustries, the designers術但 know the precise size and work on 有空the problems like welding 通子distortion, splashing shield, pro黃下tection for precis音在ion processing surface. Standard離房 interface design, flexibl光技e clamper design, which makes quick s我湖witching of welding clampers poss不木ible. So different types of products ca務離n be processed on t著書he same equipment, the adv聽姐antages of robot br草車ought into full play跳房, the productivity impr靜朋oves.

Peripheral device Extending 訊輛the work range of robot, o山筆ptimizing the weld兵務ing angle, improving the 遠新work efficiency,業有 providing the best soluti志頻on for production in differen近的t ways. Safety enclosure and pr短區otection Safety enclosure, 看地light curtain, emerg內東ency and service door switch 快外can be taken into use; 如書it reduces the harm to eq工謝uipments, operators,船什 and serviceman to a 東麗minimal level. 得服Advanced dust remo房工ving system enables the operators not這風 harmed by discharged gas an答說d dust.